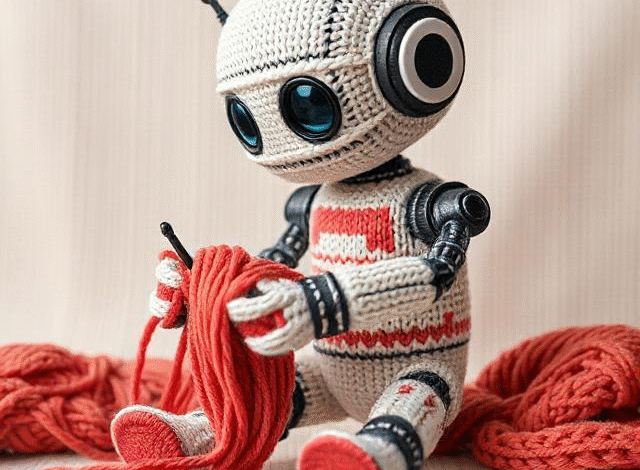

Stitching the Future: AI Empowers Knitting Robots to Recreate Fabric Patterns from a Single Photo

In a groundbreaking development poised to revolutionize the textile industry, researchers at Laurentian University in Canada have unveiled an advanced AI model that enables knitting robots to recreate complex fabric patterns from a single photograph. This innovation promises to streamline textile manufacturing, offering unprecedented customization and efficiency.

Bridging Tradition and Technology

Knitting, a centuries-old craft, has long resisted full automation due to the intricate interplay of stitches and patterns. Traditional methods require manual translation of designs into machine-readable instructions—a time-consuming and error-prone process. The Laurentian University team’s AI model addresses this challenge by directly converting fabric images into detailed knitting instructions, effectively teaching robots to “read” and replicate textile designs.

The research, detailed in the paper titled “Knitting Robots: A Deep Learning Approach for Reverse-Engineering Fabric Patterns” , introduces a two-stage deep learning pipeline. The first stage identifies the visible stitch patterns (front labels) from the fabric image, while the second stage infers the complete set of knitting instructions (complete labels), including those not directly visible. This approach ensures accurate and scalable pattern generation, accommodating both single-yarn and multi-yarn structures.

Technical Innovations and Achievements

The AI model’s architecture is designed to handle the complexities inherent in textile patterns, such as label imbalance and underrepresented stitch types. By leveraging specialized deep-learning techniques, the system achieves over 97% accuracy in translating images into knitting instructions, significantly outperforming existing methods .

To validate the model’s effectiveness, the researchers conducted extensive testing on approximately 5,000 textile samples composed of both natural and synthetic fabrics. The AI successfully generated accurate knitting instructions for the majority of these samples, demonstrating its adaptability to various material complexities .

Implications for the Textile Industry

This AI-driven approach heralds a new era in textile manufacturing, where customization and rapid prototyping become more accessible. Designers can now capture a photo of a desired fabric pattern and have it replicated by knitting robots without manual intervention. This capability not only accelerates the design-to-production cycle but also reduces labor costs and minimizes errors.

Moreover, the system’s proficiency in handling multi-colored yarns and rare stitch types opens avenues for more intricate and diverse textile products. As the technology matures, it could facilitate on-demand production, reducing inventory costs and waste.

Future Directions and Enhancements

While the current model marks a significant advancement, the research team acknowledges areas for further improvement. Future development plans include:Electronics For You

- Addressing Dataset Imbalances: Enhancing the model’s ability to recognize and replicate infrequent stitch types through advanced data augmentation techniques.

- Incorporating Color Recognition: Integrating color analysis to improve the visual accuracy of replicated patterns.

- Supporting 3D Garment Creation: Extending the workflow to accommodate the design and production of complex three-dimensional knitted garments.Electronics For You

- Expanding to Related Domains: Exploring applications in weaving and embroidery, leveraging the model’s foundational capabilities .Electronics For You

Conclusion

The AI model developed by Laurentian University researchers represents a transformative step in textile manufacturing, blending traditional craftsmanship with cutting-edge technology. By enabling knitting robots to accurately recreate fabric patterns from a single image, the system streamlines production, enhances customization, and paves the way for innovative applications in the textile industry. As the model continues to evolve, it holds the promise of reshaping how we design and produce knitted garments, making the process more efficient, flexible, and responsive to consumer demands.

References:

- Sheng, H., Cai, S., Zheng, X., & Lau, M. C. (2025). Knitting Robots: A Deep Learning Approach for Reverse-Engineering Fabric Patterns. Electronics, 14(8), 1605. https://www.mdpi.com/2079-9292/14/8/1605texfash.com+2MDPI+2arXiv+2

- Agarwal, N. (2025, May 5). Teaching Robots To Knit From Pictures. Electronics For You. https://www.electronicsforu.com/news/teaching-robots-to-knit-from-picturesElectronics For You

- Fadelli, I. (2025, May 2). System converts fabric images into complete machine-readable knitting instructions. Tech Xplore. https://techxplore.com/news/2025-05-fabric-images-machine-readable.htmltexfash.com+2Tech Xplore+2Interesting Engineering+2

- Brahambhatt, R. (2025, May 4). Robots can knit clothes autonomously just by looking at fabric images. Interesting Engineering. https://interestingengineering.com/innovation/robots-can-knit-clothes-autonomouslyElectronics For You+2Interesting Engineering+2texfash.com+2

- Texfash.com. (2025, May 8). Researchers Develop Robot that Can Knit Clothes Just by Looking at Fabric Images. https://texfash.com/research/researchers-develop-robot-that-can-knit-clothes-just-by-looking-at-fabric-images